1. Manufacturing principle:

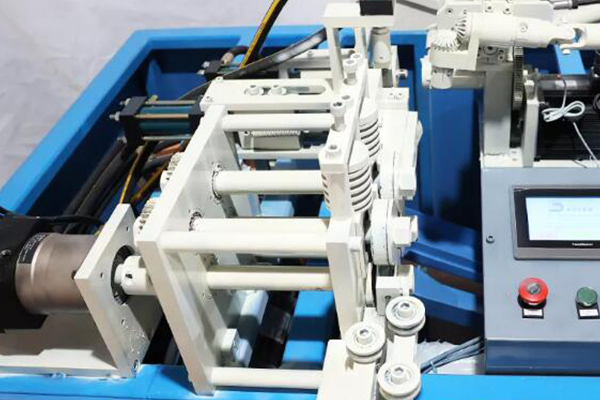

Mattress spring machines adopt advanced automation technology to process metal coils into springs of various shapes and specifications through a variety of precision processing technologies. After precise measurement and adjustment, these springs are combined according to the design requirements to form the supporting structure of the mattress. During the manufacturing process, the machine uses a variety of processes such as high-speed cutting, bending, and welding to ensure that each spring has excellent elasticity and durability.

2. Technology:

The mattress spring machine involves a variety of process technologies in the manufacturing process. The following introduces several important processes:

– Spring coil manufacturing: High-speed cutting equipment is used to cut the steel wire into the required length, and then the straight metal coil is bent into the required shape by the bending machine. Different shapes and wire diameters can be adjusted according to the different requirements of the mattress.

– Spring assembly: The bent springs are assembled into the spring support structure of the mattress according to the prescribed arrangement through the automatic assembly machine. The machine ensures the exact spacing and position of each spring, ensuring the mattress is evenly supportive.

– Spring connection: The springs are connected together by welding equipment to form a whole with a stable structure and reliable strength. The welding process ensures the reliability and durability of each joint.